The MCG project conducted on the premises of Schiedel (location Trucazzano) was aimed at a dramatic reduction in setup times for our production facilities.

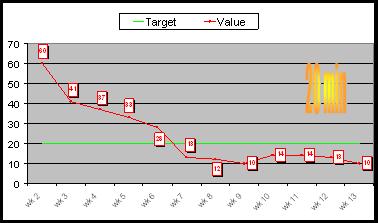

At the start of the project, setup time for, e.g., a production facility was 60+ minutes. Results of a value stream analysis suggested that it was feasible to conduct a large part of the setup process externally or in parallel, which was likely to lead to a reduction in setup time to 20 minutes.

In accordance with the 4-step rapid setup method, the project team implemented the following measures to reduce setup time:

Conversion of internal into external setup time

- Reorganisation of setup preparations using new carts.

- Outsourcing all non-value-added activities, such as preparing rollers, changing tools, etc.

Reduction in internal setup time

- Indexing tool combinations

- Standardising trial runs

- Simplifying machine loading

Paralleling the remaining setup activities

- Establishing a setup plan, with site conditions taken into consideration

- Procuring the necessary tools

Visual management and training of the staff

- Continuous monitoring of setup times and documenting results per machine.

- Introduction of a qualification matrix for all members of staff on the various shifts.

- Start of a continuous improvement process to further reduce internal setup times.

Within seven weeks, the total impact of the above measures led to an average reduction in setup times to 13 minutes (11 minutes, in the best case), which greatly improved the overall flexibility of the production system. It is obvious that reduced setup times not only mean more time for production proper, they also allow a significantly speedier and more economical response to changing market demands.