Increase in productivity between 25% and 180%!

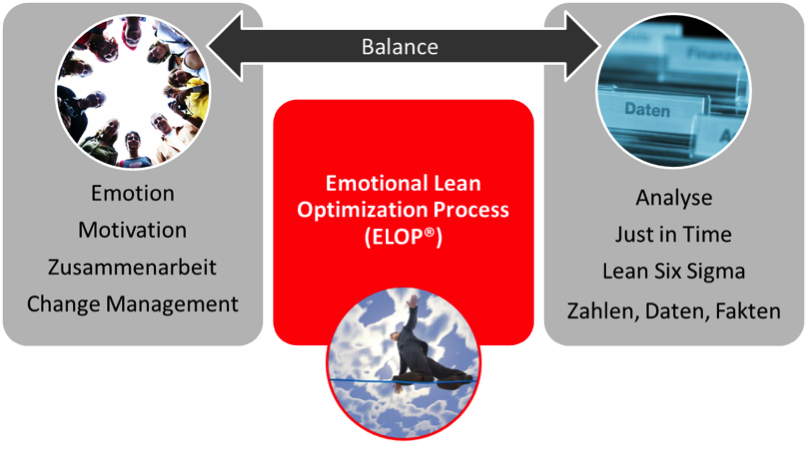

The Emotional Lean Optimization Process (ELOP) enables dramatic increases in productivity due to the combination of emotions and analytics. Under consideration of the whole supply chain and the satisfaction of the employees, ELOP takes effect on all three dimensions – quality, time (speed) and costs – of the “performance triangle”. Companies which have relied on ELOP were able to achieve the following results:

- Setup time reduction of 78%

- Lead time reduction of 50%

- Stock turnover were tripled, Production area minus 33%

- Increase in productivity in manual production of 180%

- ELOP pays off – Return on Investment between 1:5 right up to 1:11

Overview – Contents of ELOP

- Project marketing (Integration of employees)

- Stakeholder analysis (Identification of Key-Players)

- Permanent information (Change agent team)

- Project organisation (Core-team + shop floor team)

- FAQ’s (Response to open questions and fears of employees)

- Quantity structure analysis (ABC/XYZ Analysis)

- Video analysis (Value added analysis)

- Production capacities (Evaluation of needs in the future)

- Takt (Continuous flow)

- Kanban system (Material availability)

- Impementation (Pilot project and roll-out)

REFERENCES

SUCCESS STORIES

- € 3 M Cost Reduction with BigStep® at Miba Sinter Austria

- Lean Six Sigma deployed in an order fulfilling process – Increasing EBIT from 2% to 9.5% within 18 months

- Profits significantly increased at Greiner Bio One using the BigStep® Method

- Six Sigma increases productivity in the service sector from 70%-80%

- TOP – Truccazano Optimization Project